Product Overview

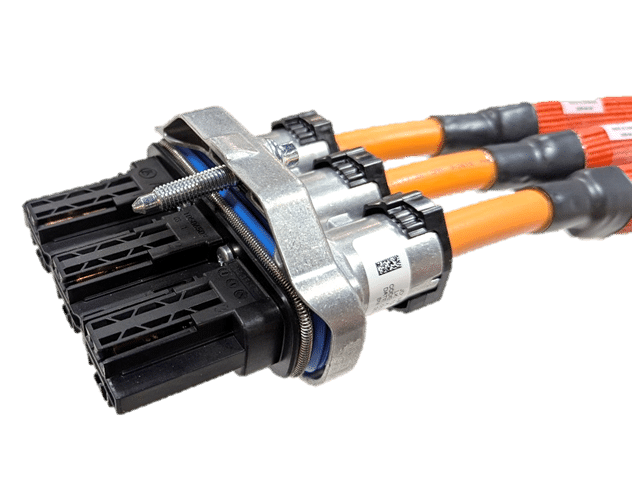

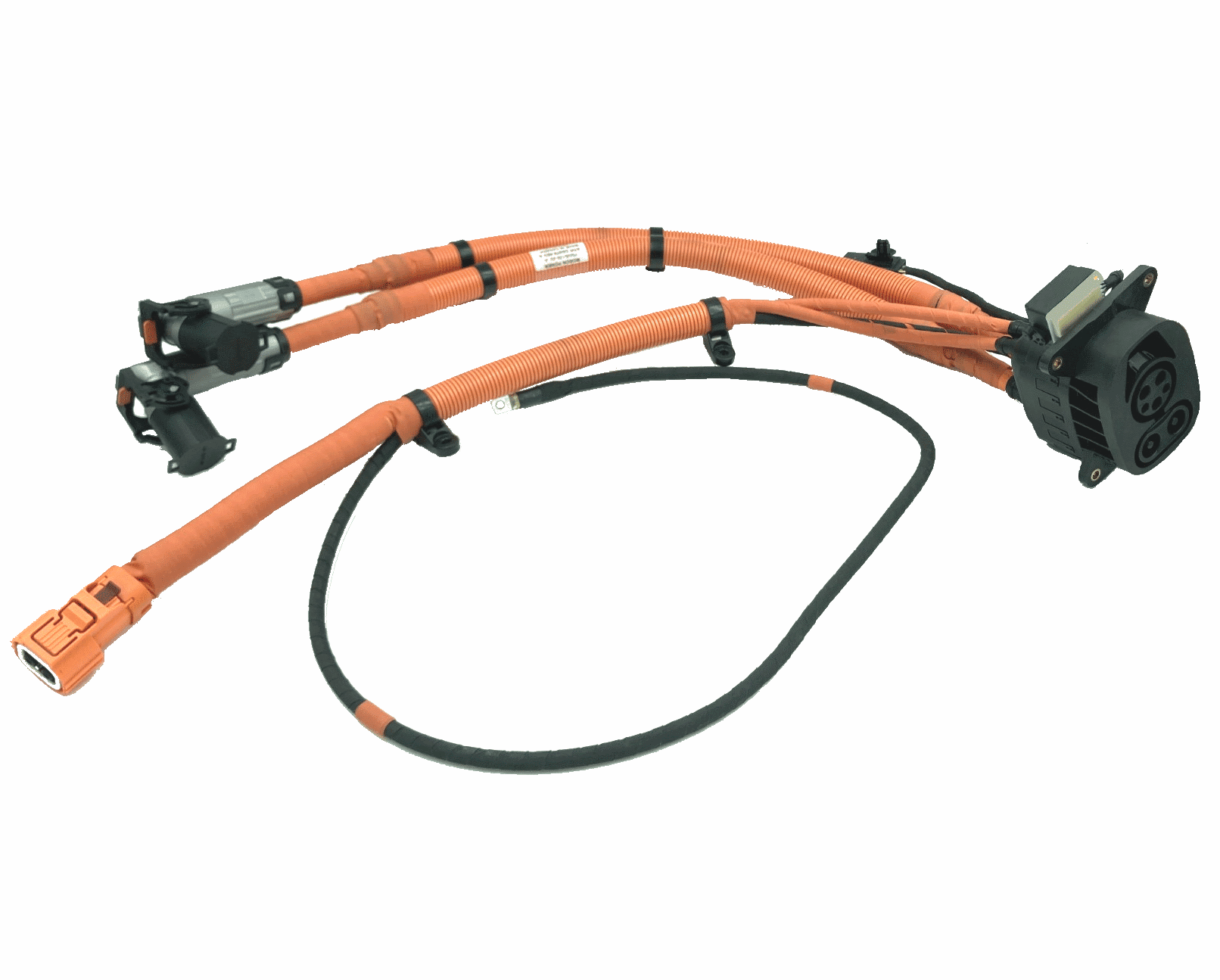

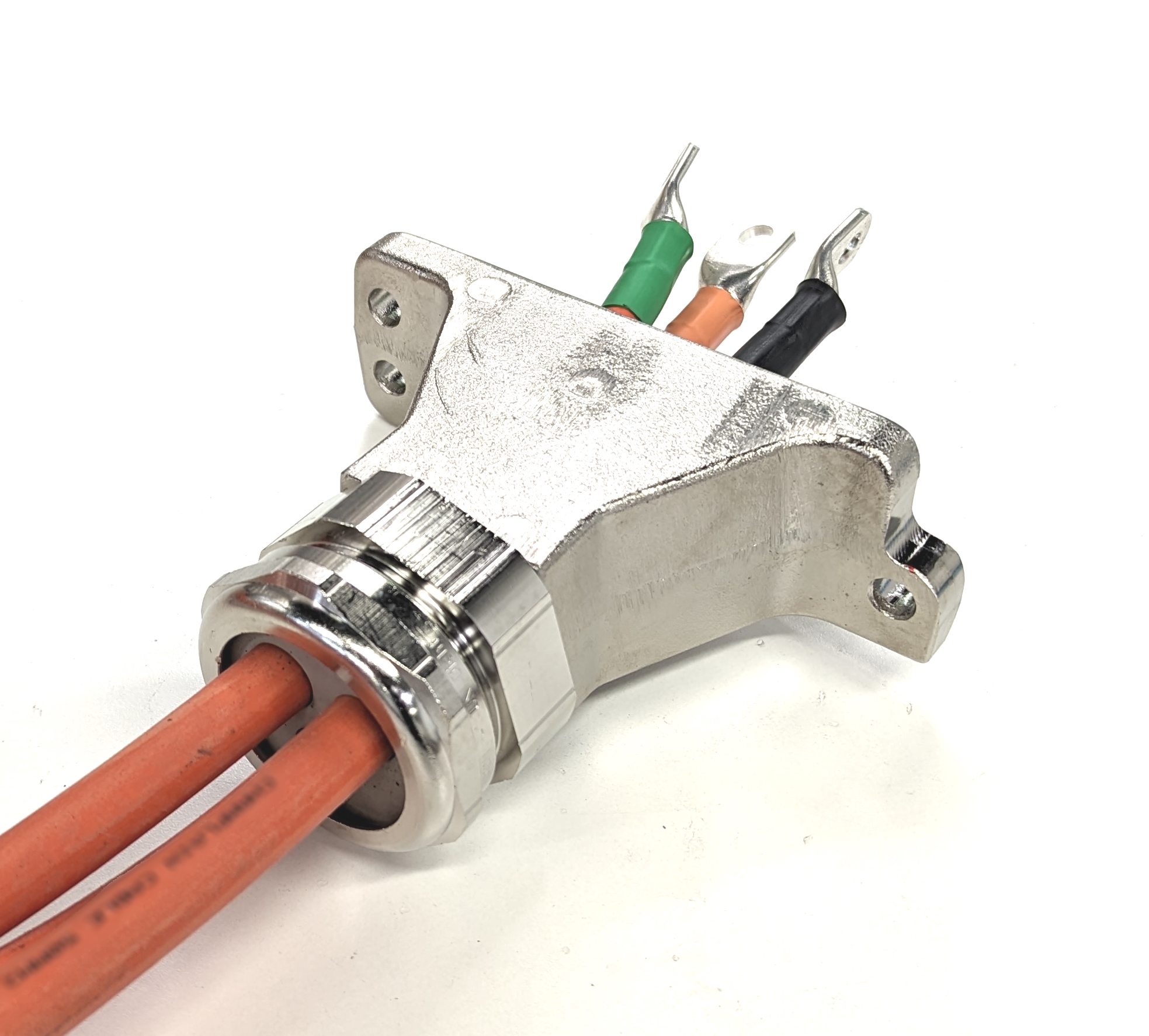

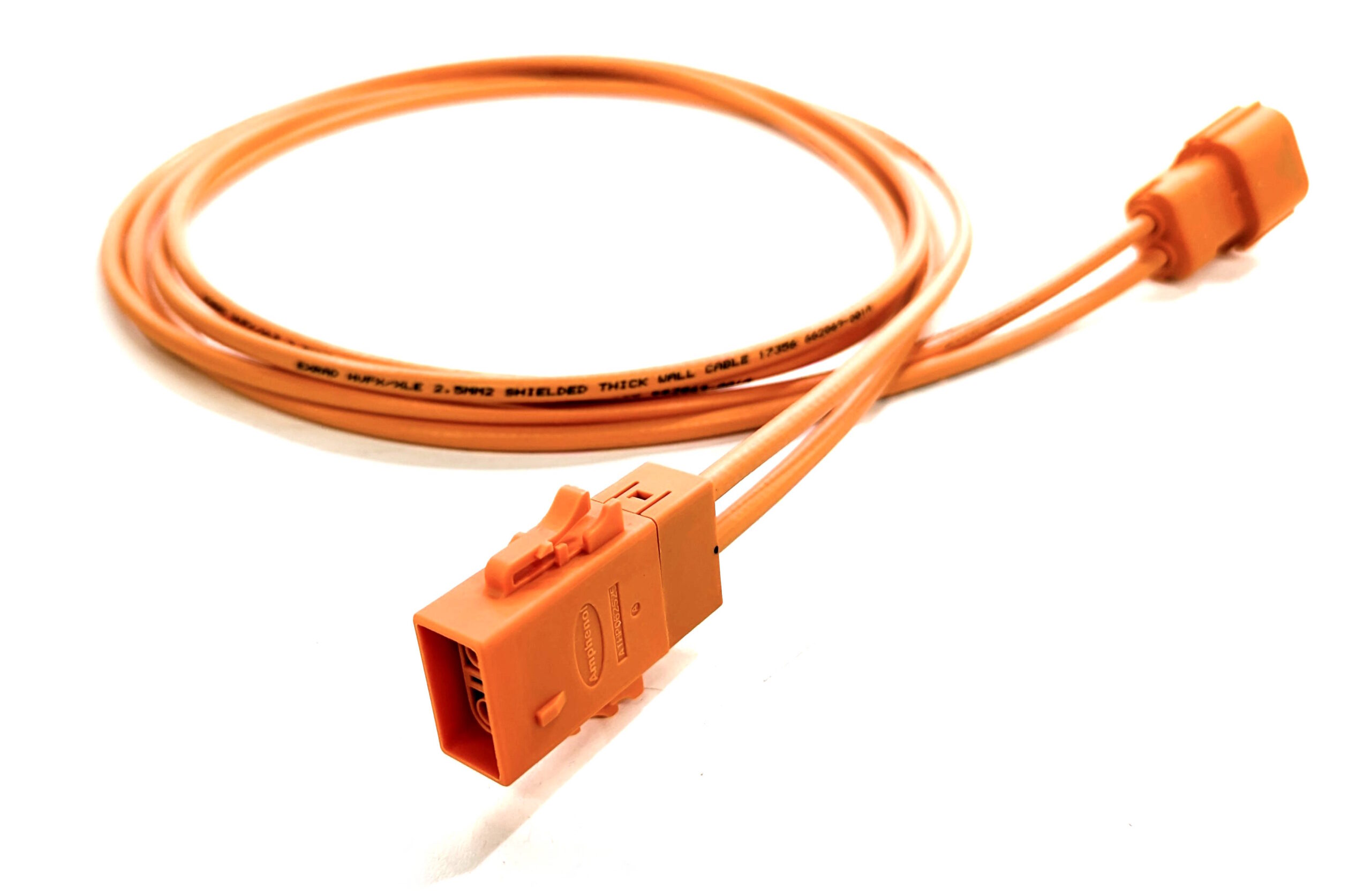

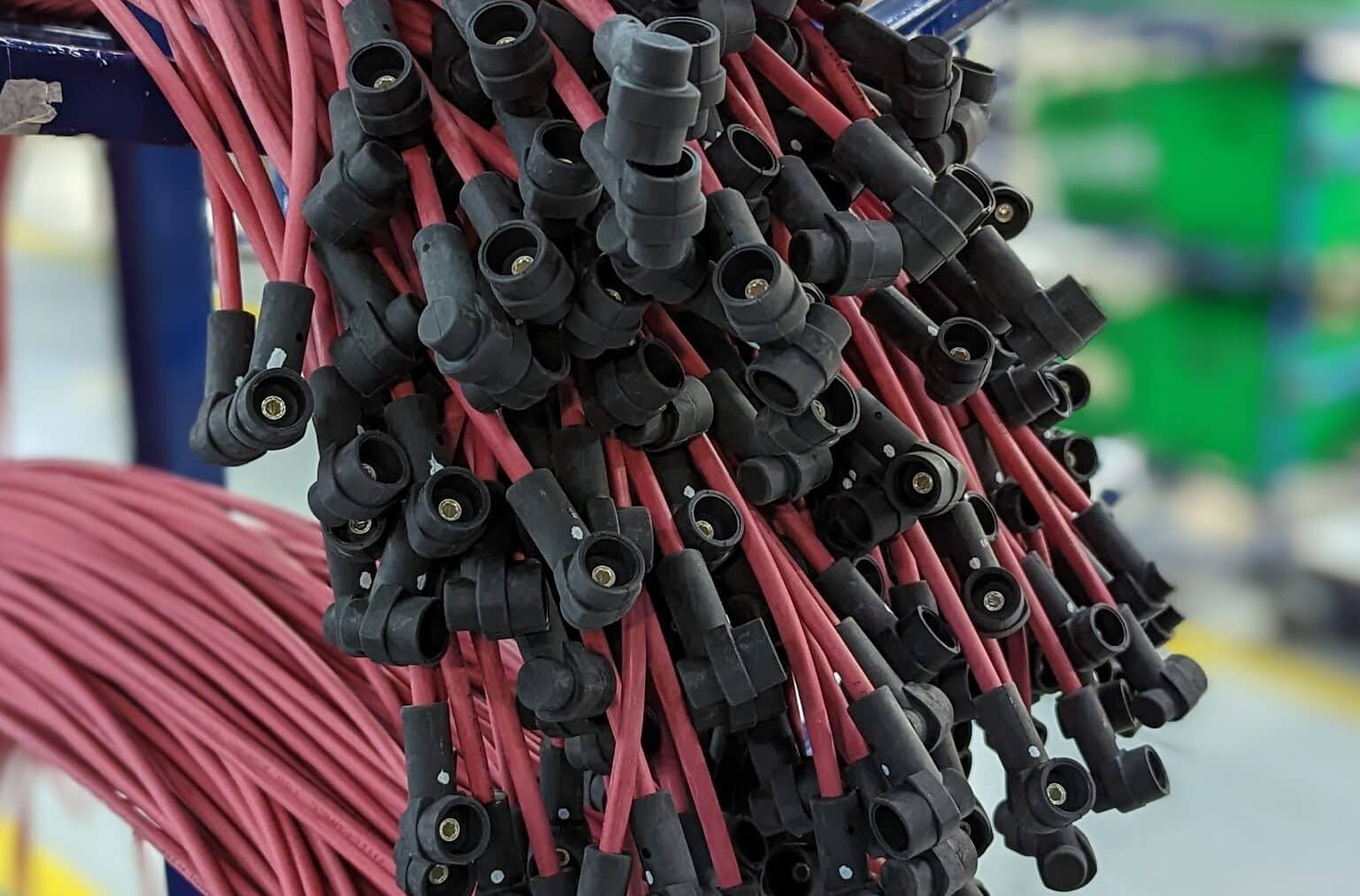

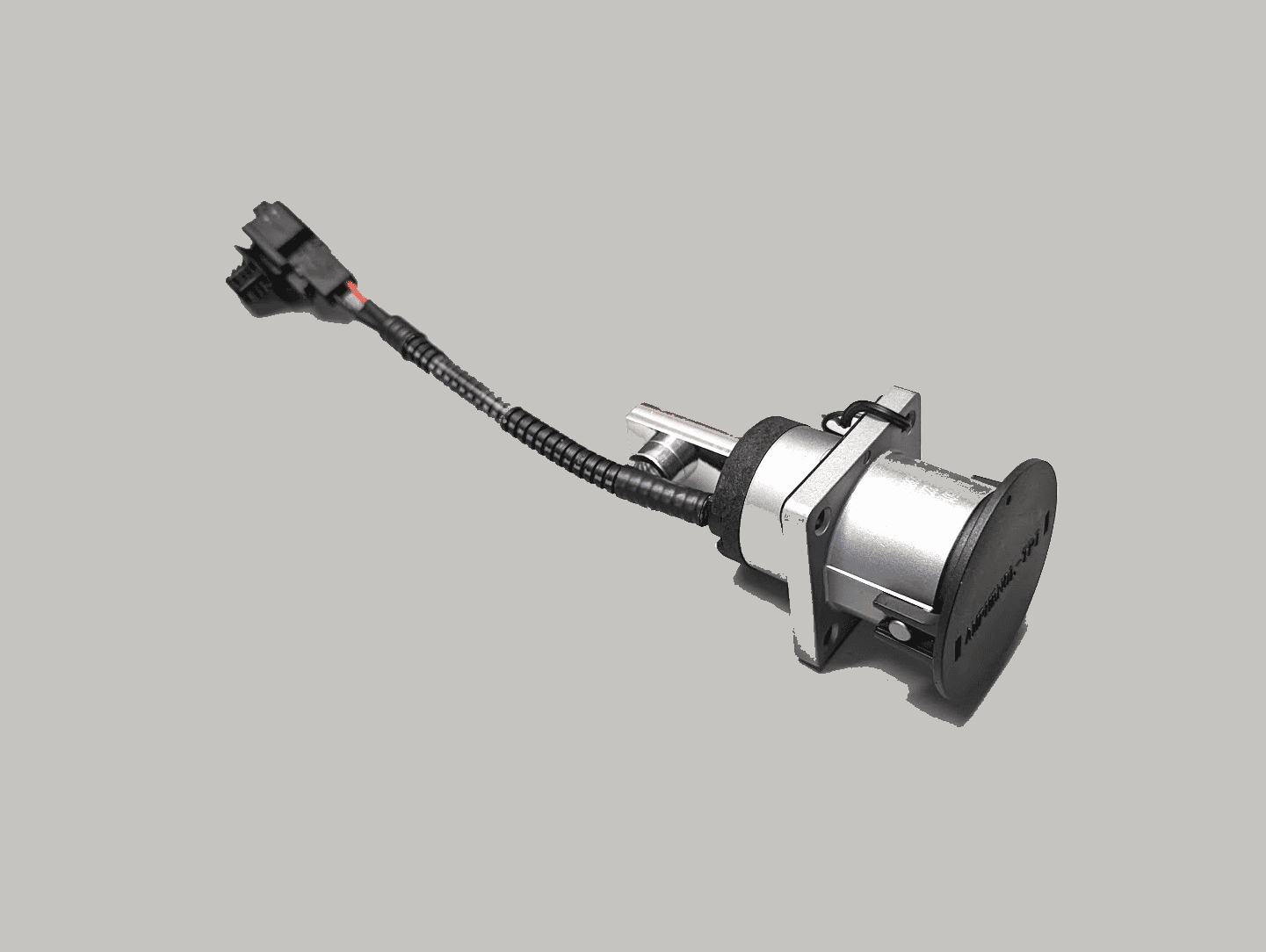

ATPI not only provides high voltage connectors, we build high voltage cable assemblies for EV/HEV and other electrification applications using Amphenol and non-Amphenol connectors for primary power distribution, accessory devices, battery connections and charge port assemblies. Quality is critical to safety – all assemblies are 100% tested for continuity, hipot, and IR at minimum. Additional capabilities for pressure/leak testing, functional testing, presence detection, orientation, 4 wire resistance, serialization, submersion and more. Options available for prototype, low volume and high-volume production.

Features

- Production and Prototype Services

- Cable termination and mechanical assembly capabilities

- HVIL customization of receptacles (end termination, routing, sleeving, clips, etc.)

- Competency with Amphenol and non-Amphenol connectors (ex. Aptiv, TE, Kostal, Hirschman, Rosenberger, Phoenix Contact and more...)

- Assortment of high voltage cable on hand (PowerLink USA, H+S, Champlain, Coroplast, Bizlink and more)

- Crimp Validation & Die Design, In house tooling options for expedited production

- Mechanical Assembly (Brackets, Busbars, Housings, etc.)

- Hipot, IR, Continuity, Resistance, Presence/Orientation, Functional, Leak, and Pressure testing options

- 3D Routing - Build and Verify to final routed position

- Injection molding value-add capabilities

- Ultrasonic weld and crimped terminations

- Testing traceability and serialization

Specifications

- Voltage ratings of 1500VDC and greater, HiPot testing up to 12k VDC

- Current testing up to 800A